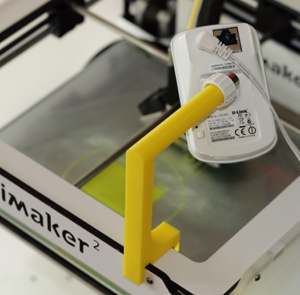

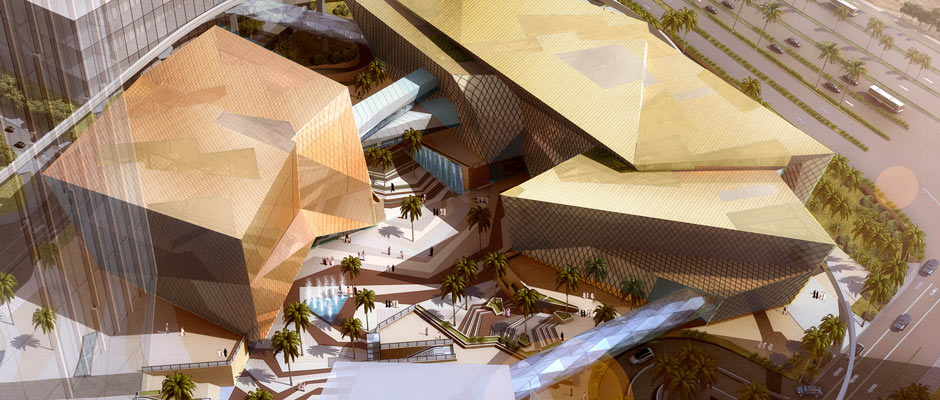

I stood up a 3D printing studio for a highly-regarded structural engineering firm. This project included acquiring the equipment, training staff, and developing procedures to incorporate that capability into project teams that could benefit from advanced prototyping. “Marvin” (as our Ultimaker 2 printer was affectionately known) was put to use creating prototypes to help explore structural conditions such as a cast connection node for the San Ysidro Legal Point of Entry and the innovative Speed Core system for the Rainier Square Tower. The long print times led us to develop a system to monitor Marvin from home so we eventually added a webcam to monitor the print bed and a web-controlled power switch (this was before they were widely available) to disable Marvin remotely when necessary.