PROBLEM

As part of the Climate Pledge Arena project, we were designing the shoring walls of the perimeter of the site. The geotechnical team completed their designs outside of the Revit BIM but we wanted to be able to deliver the design in BIM for cross-discipline coordination. This could have been done manually but the fast-paced nature of the project and volume of elements to be modeled required an automated solution.

SOLUTION

While the design team wasn’t familiar with Revit, I wanted to arm them with the capabilities to create the model on their own to speed up design -> delivery. Additionally, the designers wanted to develop a bit of experience with graphical programming. In order to address these needs, I developed the following:

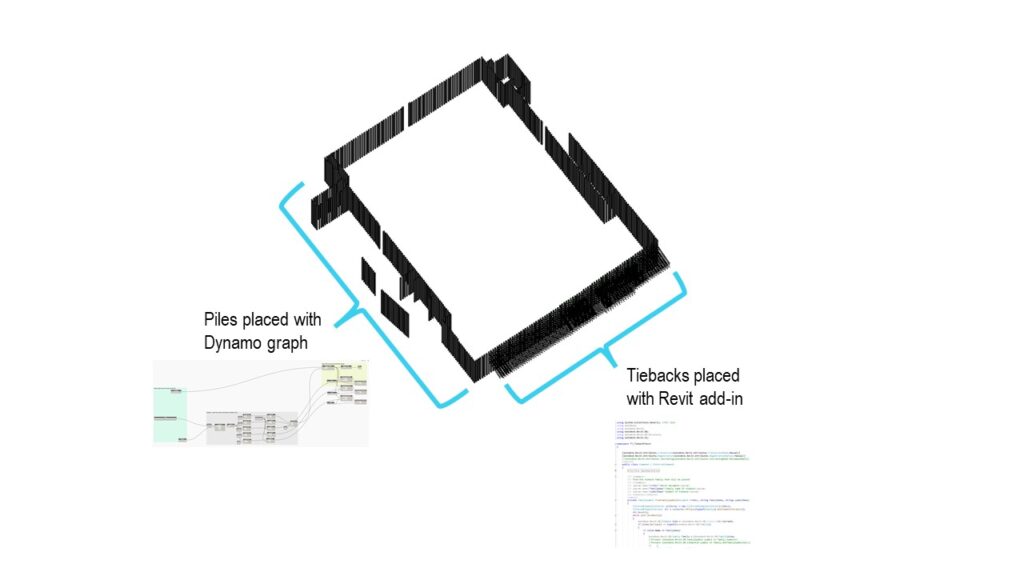

- Pile Modeling

- developed a custom Revit family

- modified the standard design spreadsheet

- developed a Dynamo script that models the piles in Revit

- Tieback Modeling

- developed a custom Revit tieback family

- modified the standard design spreadsheet to relate to the pile identifiers created above

- developed a custom Revit add-in that models the tiebacks in Revit

- Deployment and Documentation

- created a brief training to bring the design team up to speed

- installed the adding and pre-requisites for the team members involved

IMPACT

As shown in the videos below:

- 550 piles and 460 tiebacks modeled in seconds. The video only shows one wall but you can imagine that it would have taken weeks to model the thousands of tiebacks when every wall is included.

- Introduced 3D model and verification to a team that works otherwise in 2D. This 3D model also allowed design partners outside Thornton Tomasetti to coordinate utility locations and sequencing with these foundations. The modeled elements were also used to help coordinate right-of-way impacts with stakeholders at the City of Seattle.